LABORATORY-TESTED QUALITY

Contemporary, automated, and certified manufacturing facilities ensure that every component bearing the MILES trademark, regardless of its origin, adheres to the highest standards. These factory lines are designed to maintain critical product features within specified tolerance limits.

The integration of automation and robotics in the factories ensures the consistent production of each part, whether it’s the initial piece, the thousandth, or the millionth from the same batch. This reliability guarantees that drivers can depend on the parts not to fail when needed most.

Unparallel precision

State-of-the-art, automated, and certified factories produce every component bearing the MILES trademark to the highest standards, regardless of its manufacturing location. These factories employ advanced production lines that ensure critical product features remain within specified tolerance limits.

Through automation and robotics, these factories guarantee the reliability of every part produced, whether it’s the initial piece, the thousandth, or the millionth from the same batch. This assurance means drivers can trust that the components won’t fail when they’re needed most.

STEP-BY-STEP QUALITY CONTROL

The MILES parts production process incorporates rigorous and meticulously detailed control tests at various stages, including both on the production lines and during final assessments before the product is deemed ready for sale.

Every individual part undergoes thorough testing utilizing professional-grade systems and is closely monitored with advanced tools. These measures are implemented to ensure not only that the product meets the consumer’s requirements but also to guarantee its safety and proper functionality in use.

IATF-16949 CERTIFICATION

All plants where the MILES products are manufactured meet the strict quality requirements imposed by the IATF 16949 technical specification. This guarantees that every part is manufactured according to the strict standards adopted for top-quality products.

ECE R90 TYPE-APPROVAL

We adhere to all European standards outlined in the ECE R90 type-approval. MILES brake discs, pads and shoes undergo comprehensive testing at specialized and authorized testing facilities, which validate their suitability for sale in the aftermarket. The exceptional quality of MILES components ensures that they satisfy all the criteria outlined in this directive and hold the necessary R90-2 type-approval.

- Speed sensitivity

- Hot braking performance at over 500°C

- Cold equivalence

- Compressibility

- Cold shear

Crafting Perfection

1.

Market research and prototyping

The development process begins with thorough market research aimed at identifying product and vehicle requirements within the market-place. Once a product opportunity is identified a MILES specification is defined and prototype product is created. Before being commissioned for production, this prototype is meticulously analysed against specification to ensure performance and correct fitment.

2.

Material Selection & Testing

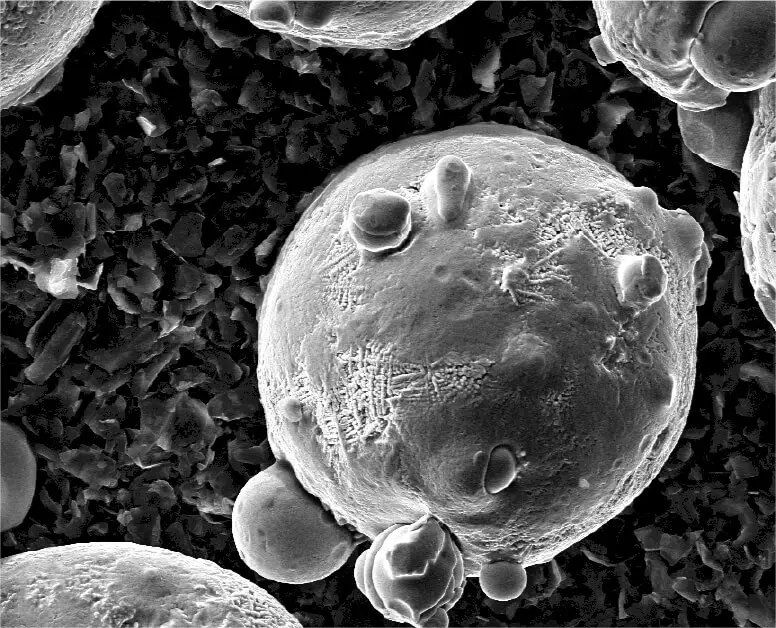

During the mass production phase only the finest raw materials are selected and each batch of material is sample tested for hardness, tensile strength, chemical composition and structure to ensure a material specification that meets the MILES standard.

3.

Precision Manufacturing

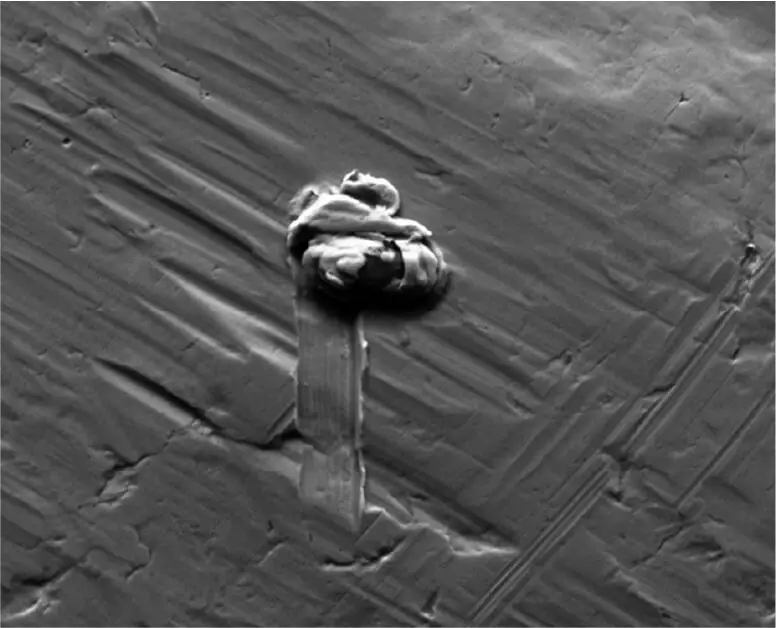

To form the perfect brake disc the raw material is then machined using state-of-the-art KUKA and FANUC autonomous machinery. These computer controlled machines are employed to ensure absolute precision and consistency for each and every MILES disc.

4.

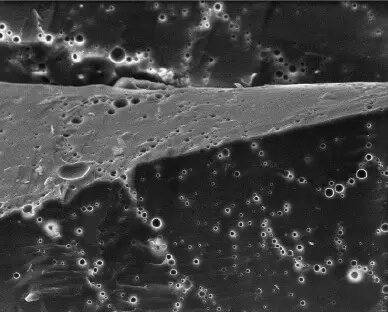

Specialised Coating

Each MILES coated brake disc is then subjected to a 9-stage process to apply an advanced formulation anti-corrosion coating. This coating is applied to all areas of the disc, including the hub and friction surface, to a maximum thickness of 25 microns, ensuring effective rust protection and premium aesthetics.